Capabilities & Services

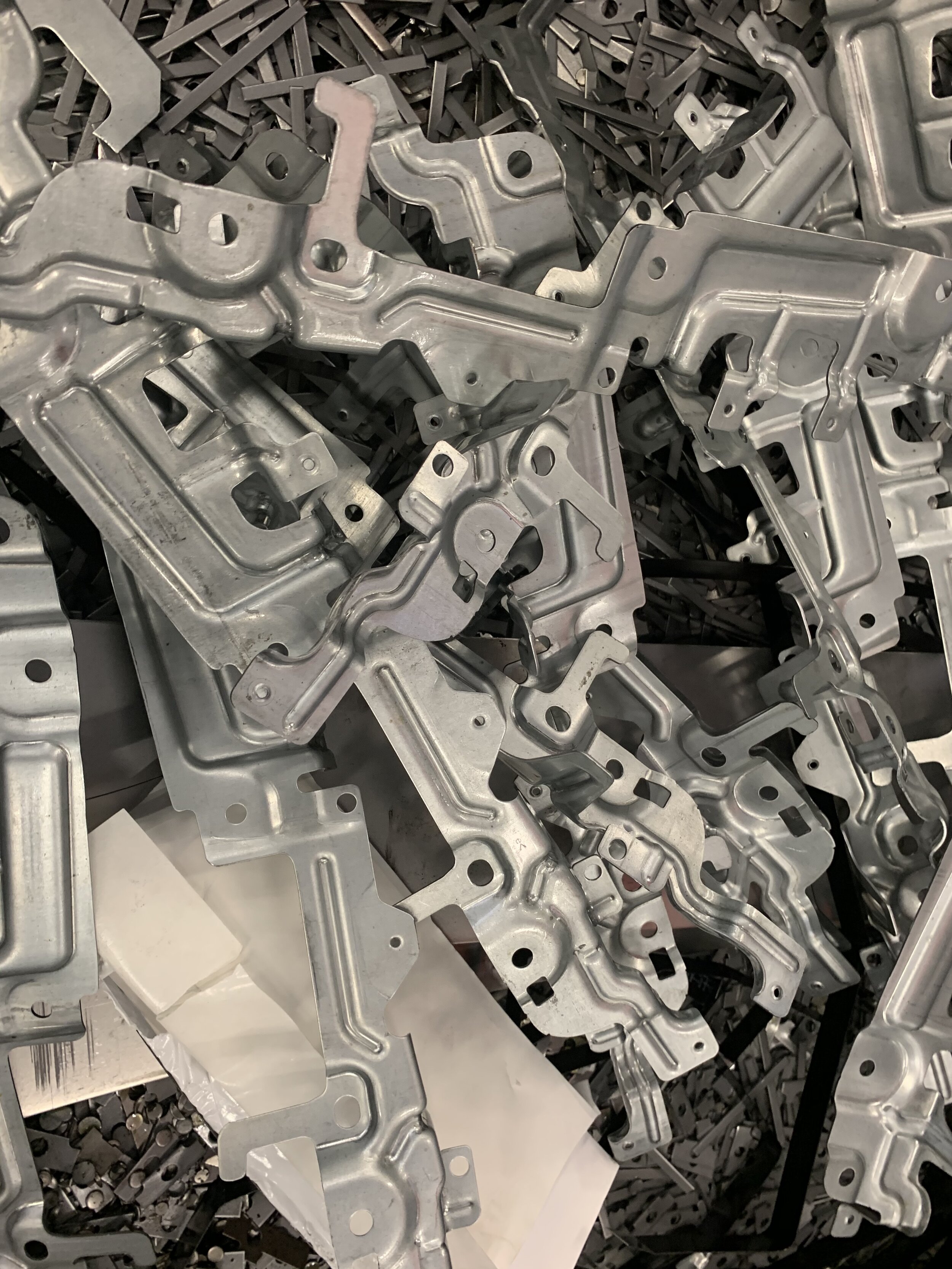

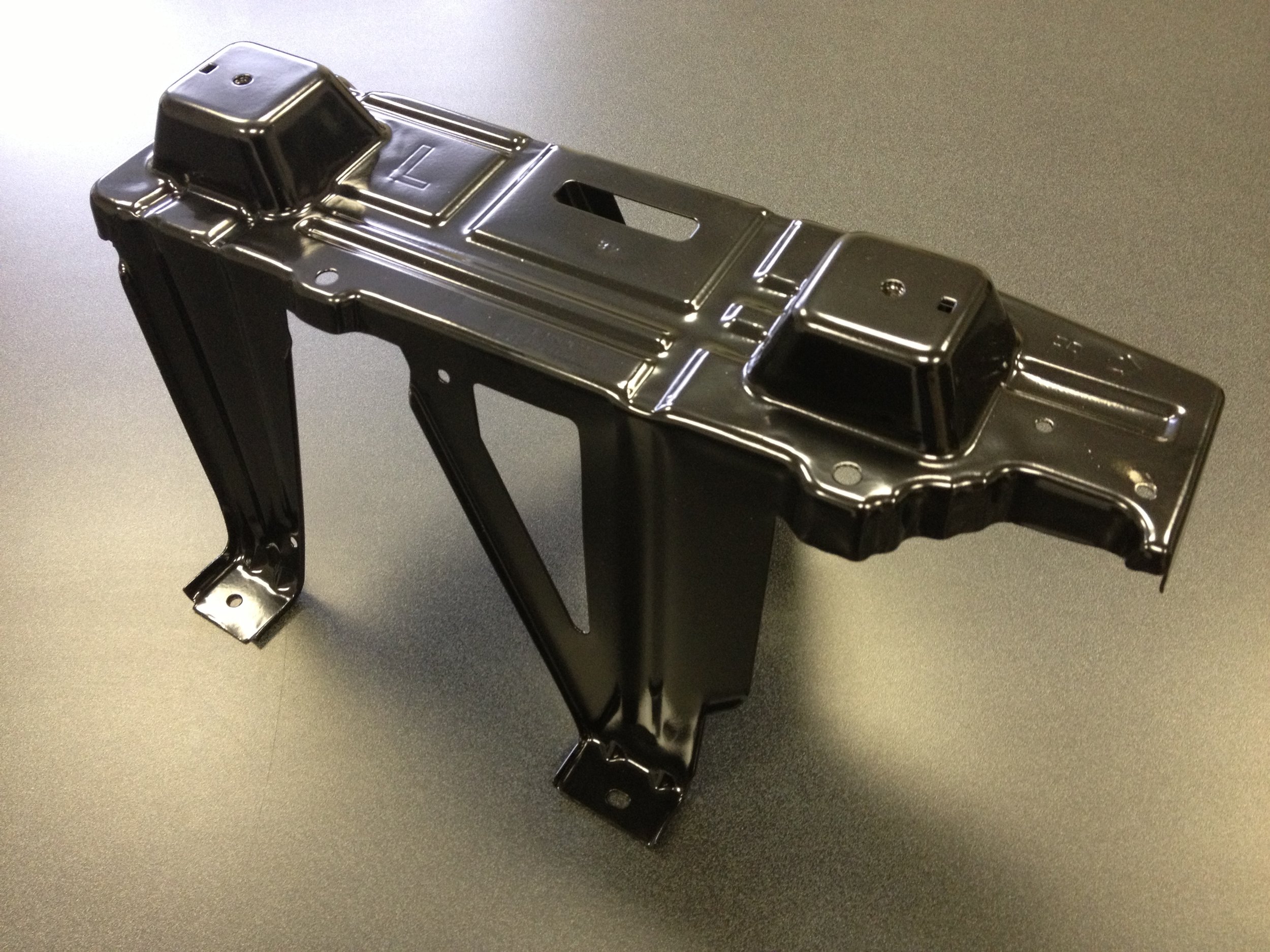

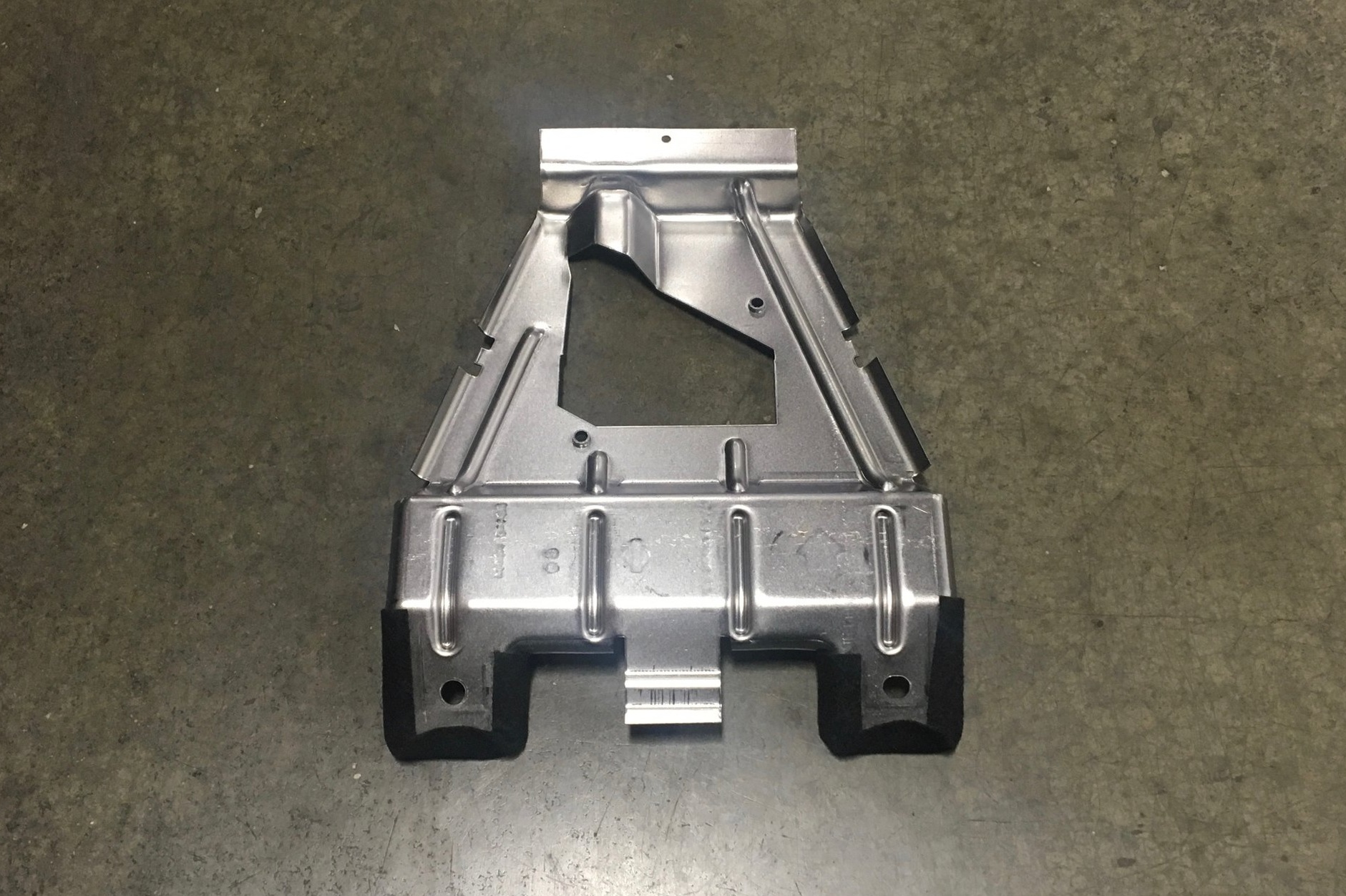

Our stamping capabilities range from 60 to 400 tons. We specialize in small to medium-size stampings produced with progressive complete or tandem off line tools. TAS-CO works primarily with low carbon and HSLA steel but also produces parts with stainless steel, aluminum, copper and brass. We produce a variety of parts including deep drawn stampings and those with in-die clinch nuts or in-die tapping.

TAS-CO uses material that ranges in thickness from .015'“ to .375”.

Stamping Dies

Progressive

With In-Die Clinch Nuts

With In-Die Tapping

Hand Transfer

Blanking

Offline or Secondary Dies

Coining and Forming

Hand Transfer

With In-Die Clinch Nuts

With In-Die Tapping

Drawing or Deep Drawn Dies

Compound Dies

metal stamping

tool and die maintenance

TAS-CO's in-house tool and die maintenance aids in the longevity of the dies and consistency of the parts. By keeping this service in house, we are able to keep costs down and pass along savings to our customers. Due to our quality built dies and proper maintenance, our tools have been able to last the life of the program and beyond into further business with the same customer.

Tool Design

CAD modeling (TAS-CO supports STEP, Parasolid, and IGES)

Modeling with 2D (DWG and DXF) and 3D Data

General Tooling Maintenance

Tooling History

Tooling Modifications

We service and maintain all of our customer’s tools for the life of the program.

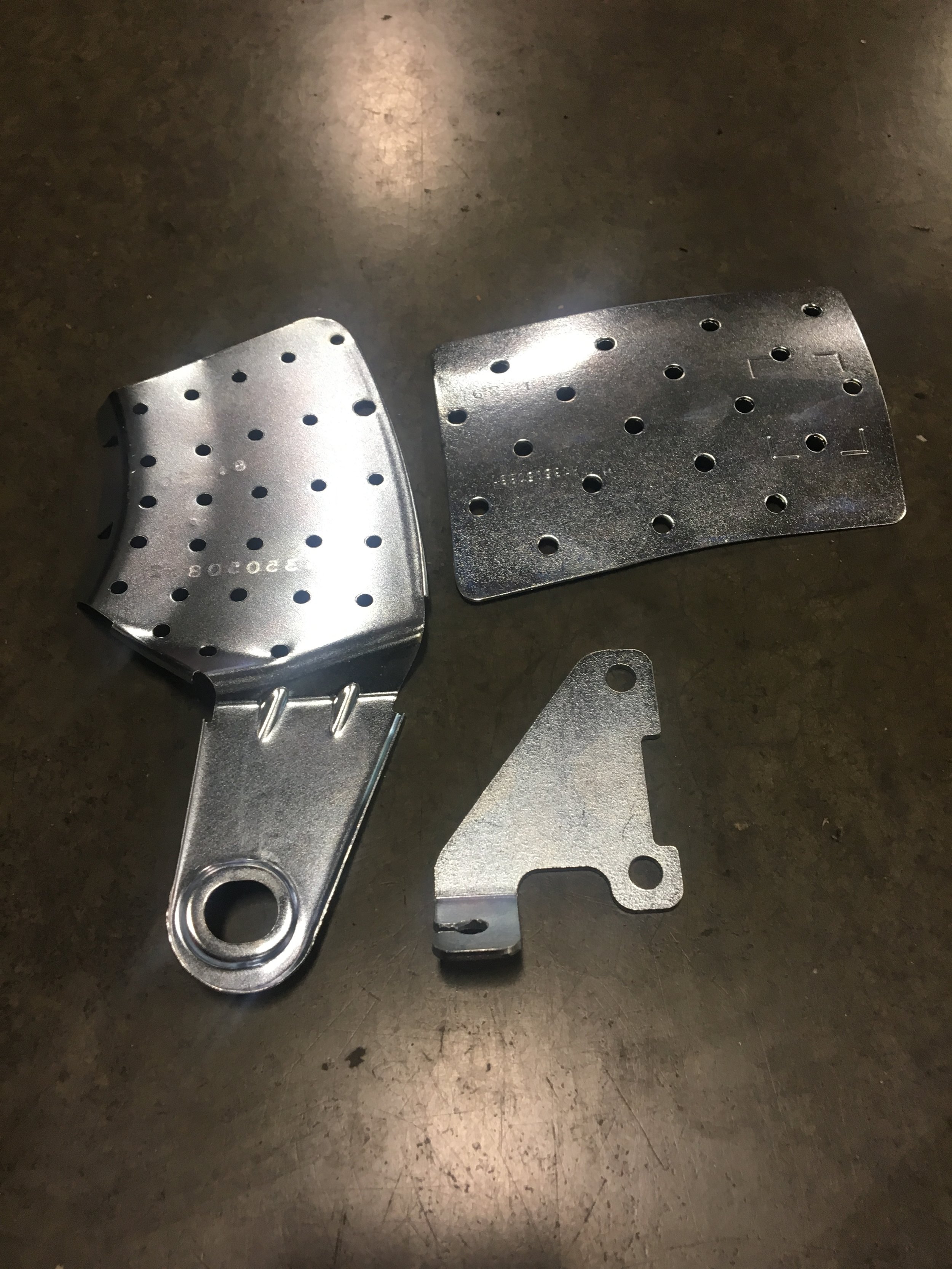

welding & Sub-Assembly

TAS-CO offers resistance welding and sub-assembly services. If your stamping needs weld nuts, studs, tape or velcro added to them, we can provide this service.

TAS-CO can provide the following value-added services:

plating

painting

powder coating

heat treat

third party part inspection

material analysis

e-coating